The very definition of what food is undergoing a revolution. It will be challenged by beefless beef, porkless pork, fishless fish, chickenless chicken, milkless milk, milkless dairy products and eggless eggs that will be created via the manipulation of cells, genetic engineering and synthetic biology.

Many foods may be made in the laboratory and not on the farm. The impact of the synthetic biology revolution—to help us meet the sustainability and climate change challenges of the 21st century—are transformative. The new ways food will be produced will help to reduce CO2 emissions generated by the agricultural sector, which is a major cause of climate change.

For example, study published by Nature Food indicated that soil tillage, crop and livestock transportation, manure management and all the other aspects of global food production generate more than 17 billion metric tons of greenhouse gas emissions annually. Animal-based foods account for 57% of those emissions, and plant-based account for 29%.

Of the foods analyzed in the report, beef production was the top emission emitter, accounting for 25% of the total, followed by cow milk, pork and chicken meat. For crops, rice farming was the top contributor and the second-largest contributor among all products, accounting for 12% of the total. Rice’s high contribution is due to methane-producing bacteria that thrive in the anaerobic conditions of flooded paddies. After rice, the highest emitters were wheat, sugarcane and corn.

The food transformation will also aid in the reduction of water use as agriculture accounts for about 70% of all water usage. This is particularly important given how much water resources are under stress as a result of pollution, climate change and rising global population.

An article On the Integrated DNA Technologies’ company website noted,

Synthetic biologists alter food by first identifying the gene sequences responsible for certain desired qualities, like the beefiness of beef or the sweetness of sugar. Usually, this is a protein, which is recognized, recreated chemically in a lab, and placed in yeast or bacteria cells. Fermentation mass produces these proteins, which become food or fiber ingredients.

A 2021 paper in Future Foods entitled, “Synthetic biology for future food: Research progress and future directions”, noted,

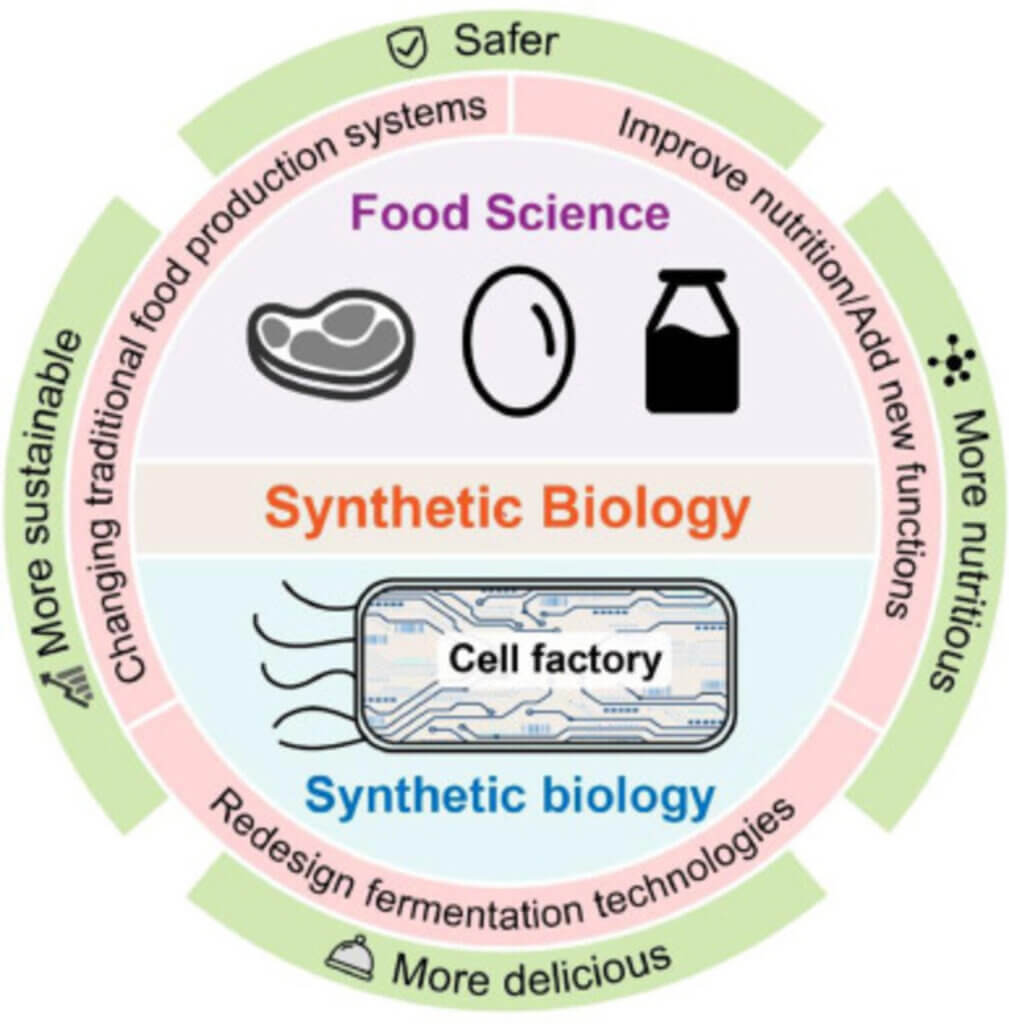

Overall, synthetic biology driven food industry has the potential to address the challenges of sustainable food supply in the future… synthetic biology can improve the traditional food production and manufacturing… The emergence of synthetic biology allows meat analogs to mimic real meat in appearance and characteristics such as color, taste and flavor, thus meeting the increasing demand of consumers for both food quantity and quality…

There are many advantages of the milk substitutes produced with the aid of synthetic biology compared with the traditional process. First, the milk producing cell factory can grow in a bioreactor, which could avoid the problems caused by the traditional husbandry such as antibiotics and hormones contamination or land occupancy. The culture period of the engineered cell is much shorter than that of the dairy cow.

Over the last few years, a plethora of companies have arisen in the food industry with the ambitious intention of changing the way food is manufactured. They have attracted a great deal of interest from investors. According to the Good Food Institute, $5.9 billion was invested in companies developing alternatives to meat, eggs and dairy between 2010-2020 with $3.1 billion of that amount invested in 2020.

New meats

Plant-based meat companies are in the forefront of the food revolution. Impossible Foods and Beyond Meat, for example, are making plant-based hamburgers. One of the main ingredients in the Impossible Burger is GMO soy which is transformed into heme that makes the burger “bleed” and taste like meat. Beyond Meat ingredients, none of which are genetically modified, include, water, pea protein, canola oil, coconut oil, potato starch, yeast extract, salt, sunflower oil, and ascorbic acid. In January 2022, KFC began selling a plant-based chicken product developed by Beyond Meat in the US and Canada.

Impossible Foods has also begun selling chicken nuggets, pork and sausage. According to the company, its pork product uses 81-85% less water, 66-82% less land and generates 73-77% less greenhouse gas emissions then conventionally grown pork. It is also developing plant-based milk, fish and eggs.

OmniFoods, of Hong Kong, has developed a plant-based pork that is sold in the US, Australia and the UK. It is made from soybeans, peas, mushrooms and rice and contains less saturated fat, less calories, and zero cholesterol compared to conventional animal-based pork products.

Mark Post, the Dutch scientist who was responsible for the first lab grown hamburger in 2013 and who co-founded of Mosa Meat, a lab grown meat company headquartered in Maastricht, Netherlands, has estimated that “one half-gram biopsy of cow muscle could in theory create up to 4.4 billion pounds of beef—more than what Mexico consumes in a year.” Mosa Meat’s objective is to produce 15,000 pounds, or 80,000 hamburgers, per biopsy. “Eventually”, Post said, we would need only some 30,000 to 40,000 cows worldwide, instead of the 300 million we slaughter every year, without the environmental and moral consequences of large-scale intensive cattle farming.” Mosa Meat hopes to sell a lab grown hamburger to the public by the end of 2022.

In 2021, Future Meat, headquartered in Rehovot, Israel, opened the first production facility for lab grown cultured meat. This was a major step in the company’s timeline for getting regulatory approval to sell its products in Israel and the US sometime in 2022. The company claims the facility can produce 500 kilograms of cultured meat per day, which is equal to about 5,000 hamburgers. The first products to come out of the facility will be a cultured chicken breast, chicken fingers, and hamburgers. The cost of the chicken will initially be $7.50 per quarter-pound serving but within 12 to 18 months the cost could decline to $2.00. The meat will be composed of 45 to 75 percent cultured meat, depending on the product, with the remainder being plant based.

In December, 2021, MeaTech 3D, headquartered in Israel, claimed it had:

… succeeded in bioprinting a 3.67 oz (104-gram) cultivated steak, primarily composed of cultivated real fat and muscle cells… it is the largest cultured steak produced to date. This groundbreaking achievement serves as an important milestone toward the goal of scaled production of cultivated bio-printed steak. The cells used in making the steak were produced using an advanced and proprietary process that starts by isolating bovine stem cells from tissue samples and multiplying them. … The printed product was placed in an incubator to mature, where the printed stem cells were differentiated into fat and muscle cells that develop into fat and muscle tissue, respectively, to form the MeaTech steak.

MeaTech’s goal is developing a true replacement for conventional steak that maximizes cell-based content rather than non-meat ingredients. The cultivated steak is comprised of real, living muscle and fat cells, and does not contain any soy or pea protein typically used in plant-based alternatives.

The company hopes to open a production facility by the end of 2022. In addition to beef, the company plans to produce chicken and pork products.

Aleph Farms of Israel produced the first steak made from cow cells in 2018. In January 2021, it announced an agreement with Mitsubishi Corporation’s Food Industry Group to bring cultivated meat to Japan followed by a deal to operate in Brazil. According to the company:

This method is to produce cultivated beef steaks relies on mimicking a natural process of muscle-tissue regeneration occurring inside the cow’s body, but under controlled conditions.

A market launch is expected this year for a thin-cut steak.

Upside Foods, headquartered in Berkeley, has developed a biological process to grow synthetic meat products by taking stem cells from animals and eggs; feeding them nutrients, carbohydrates, minerals, fats, and vitamins and then speeding up their growth in a bioreactor. Utilizing this technique, it has been able to produce beef, duck and chicken. It has indicated that its first commercially available product will be chicken. On January 25, the company announced that it acquired Cultured Decadence which makes cell-cultured seafood products such as lobsters and other crustaceans.

Another company in the cell-based meat space is Eat Just which has developed a chicken that has been approved for sale in Singapore. The company also makes a plant-based scrambled egg product and a plant-based mayonnaise. Another company that makes a plant based eggless egg is Simply Eggless, which produces a liquid or patty egg that uses Lupin beans as its main ingredient. Zero Egg of Israel is also producing a plant-based egg in a patty and liquid form. According the company, it uses 93% less water, 92% less land, 59% fewer greenhouse gas emissions and 93% less energy than conventional eggs.

A Chinese company, Cellx, is producing cell-based pork sourced from cells from a black pig. It is utilizing 3-D printing to get the look and the right proportions of the meat and hopes to achieve price parity with conventional pork by 2025.

Black Sheep Foods of the US has developed a plant-based lamb. The company has developed a class of compounds called branched chain fatty acids that account for the gamy flavor of lamb. Tofurky has developed a plant based roast beef.

Seafood

Plantish, an Israeli company, has developed the first plant based boneless salmon fillet. It is made from legume proteins and algae extracts and mirrors conventional cooked salmon in appearance, taste, texture, and structure. According to the company:

…whole-cut fillet boasts the same nutritional value of animal-based salmon, and is high in protein, omega-3s, omega-6s, and B vitamins.

It plans to begin sales in 2024.

Among the other companies producing plant-based seafood are New Wave Foods, Good Catch Foods, and Ocean Hugger Foods. The development of animal-based fish is particularly important in light of the depletion of fish stocks caused by over fishing, global warming and pollution. About 85% of global fish stocks are over-exploited, depleted, fully exploited or in recovery from exploitation.

Blue Nalu and Finless Foods make cell-based tuna. Finless Foods also makes a plant-based tuna. The Plant Based Seafood Company makes plant-based shrimp, scallops and crab cakes. Berlin-based Bluu Biosciences is planning to use cell-based technology to make fish. Dr. Sebastian Rakers, co-founder and chief science officer, said the company’s future products

… will feature both hybrid products consisting of cell-based fish and plant-based proteins in well-liked formats such as fish balls, or fish sticks and structured fish fillets.

Milk

Perfect Day has created”

…the world’s first milk protein made without animals, so you can enjoy the taste, texture, and nutrition of traditional dairy, produced sustainably and without the downsides of factory farming, lactose, hormones, or antibiotics…a third party-validated life cycle assessment…found that Perfect Day’s whey protein production reduces water use up to 99%, greenhouse gas emissions up to 97% and non-renewable energy use up to 60% compared to conventional production methods.

Perfect Day makes its milk by genetically modifying microflora to produce whey and casein through a fermentation process. They are combined with plant fats, vitamins and minerals to make a lactose-free product that has the same taste, consistency and nutritional qualities as milk. Perfect Day has attracted a great deal of investor interest. In October it raised $350 million bringing its total funding to more than $750 million.

In 2020, it launched Brave Robot Ice Cream with the Urgent Company (created by Perfect Day to develop its milk into products). In October 2021, Modern Kitchen brought to the market cream cheese that is made with milk from Perfect Day.

Ripple foods produces a pea-based milk and ice cream. There are also companies producing cell-based milk. Among them are Turtle Tree, based in Singapore and Israel based Bio-Milk. Another company producing milk without cows is Better Diary, headquartered in the UK.

Ripple uses synthetic biology and yeast fermentation to produce dairy products following a similar process to brewing beer. Their products, molecularly identical to traditional dairy.

New cheeses

New Culture uses a fermentation process to manufacture an animal-free casein protein that is used to make animal-free mozzarella cheese which it hopes to market this year. Although New Culture does not use any ingredients that are genetically modified, it does utilize genetic modification to program microorganisms to make casein proteins.

Real Vegan Cheese is a non-profit research project that is working to produce cheese using cellular agriculture. Genes for cheese proteins are added to yeast and other microflora. They are turned into “protein factories” that are used to make cheese by adding plant-based fats. Berlin-based Formo makes lab-grown cultured mozzarella and ricotta cheeses.

Chocolate

The laboratory at Zurich University of Applied Sciences has developed lab-grown cell culture chocolate. Compound Foods is using synthetic biology to “recreate” coffee on a molecular level. Atomo is producing molecular coffee that is vegan and gluten free. According to the company, it is produced with 94% less water and 93% less carbon emissions then conventional coffee. Endless West is producing and selling molecular whisky. Swiss company Evolva, has developed a way to brew vanillin from yeast using synthetic biology. Beer has been manufactured from “synthetic” yeast.

Flavors and fragrance

Synthetic biology can be used to make flavors for food and fragrances. Casey Lippmeier, VP of innovation at synthetic biology specialist company Conagen, believes that 100% of the flavors market could be served by synthetic biology. According to Lippmeier:

The thing about synthetic biology, is that in addition to making all the wonderful molecules that exist in nature, you can make brand-new ones too.

If you are making flavors in fermentation tanks, you can make them to order, and you don’t have to worry about unpredictable weather, seasonality, political instability, supply chain interruptions, heavy metals and unexpected pesticide residues that plants suck up from the soil.

The nice thing about fermentation, is that it is still biology, it really mimics what is happening in nature and in many cases, it uses the same exact enzyme, and so it gets you a formulation that in many cases cannot be reproduced with synthetic chemistry.

The very nature of the food we consume is being altered in dramatic ways using genetic engineering and synthetic biology. Meat can be made without animals, eggs can be made without chickens, milk can be made without cows and fish can be made without fish. Plant based and cell-based meats taste the same as animal-based meat and they have the same texture and look. Chocolate, vanilla, coffee and whiskey meanwhile can be made in laboratories.

The transformation of the food industry by these developments calls into question the very definition of what food is. Just as importantly, it offers the opportunity for all of us to rethink the relationship of food to our sustainable existence here on planet Earth.

Steven E. Cerier is an international economist and a frequent contributor to the Genetic Literacy Project.