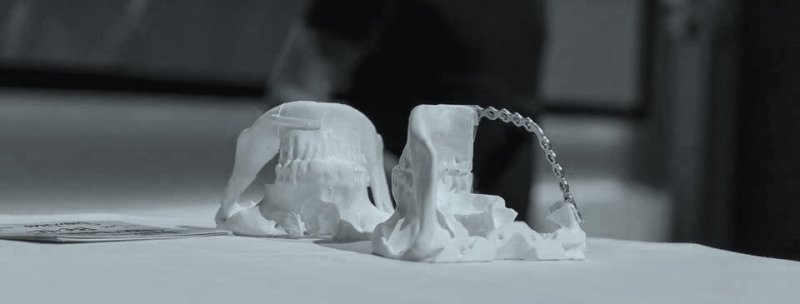

Become partially android for a couple of years while your body heals itself.

It may sound far-fetched, but for patients needing reconstructive surgery, this could soon be the pitch from Danish startup Particle3D. The company is pioneering a novel method for 3D printing lightweight, customized bone implants that fuse with your skeleton before slowly disappearing.

The technology carries a lower risk of infection and the implants are tailored to your body (and the method could soon be heading to space with astronauts!).

Traditional implants generally consist of non-degradable materials such as polymer or titanium. Particle3D uses a “bio-ink” made from tricalcium phosphate (TCP) powder particles and fatty acids. TCP been used in reconstructive surgery for decades, but is normally manually sculpted by surgeons from solid blocks into the desired implant shape. This approach can limit the potential positive effects of TCP, for example, when it comes to stimulating natural bone growth.

…

3D printing TCP enables the company to create more porous implants. The porous structures allow the implants to function as scaffolds for blood vessels and natural bone to grow, and the implants degrade over time as they are supplanted by natural bone.