Spurred by the COVID-19 pandemic, many laboratories are reorienting their research to not only look at promising compounds that occur naturally in plants, but also to manipulate plants to produce high‐value pharmaceuticals, a practice called “biopharming.” Academics and biotech companies are using molecular genetic engineering techniques to reprogram plants—including corn, potatoes, rice, and bananas, among others—to produce significant concentrations of pharmaceuticals, including vaccines. Unfortunately, this promising research is being hindered by overregulation.

Why biopharming?

Biopharming’s great promise lies in using genetic engineering techniques to make old plants do radically new things, often more cheaply than is possible with non‐plant platforms. The technology is similar to that used to insert genes into non‐plant organisms, as has been done for decades. For instance, the gene that expresses the human insulin gene was inserted into the bacterium E. coli, and the genetically modified bacteria have been the source of that critical drug since 1982. Similarly, genetically engineered baker’s yeast that contains the gene for a surface protein of the hepatitis B virus has been the source of hepatitis B vaccine since 1986.

There is great potential for cost‐cutting in the biopharming process. The energy for product synthesis comes from the sun, and the primary raw materials are water and carbon dioxide. In addition, biopharming offers tremendous flexibility and economy when adjustments in production are necessary. Doubling the acreage of a crop requires far less capital than doubling the capacity of a bricks‐and‐mortar factory, making biopharmed drugs potentially much less expensive to produce than those made in conventional ways. The quality of the final drug can meet the same standards as current fermentation technology using microorganisms, and grain from a biopharmed crop can be stored safely for long periods with no loss of bioactivity.

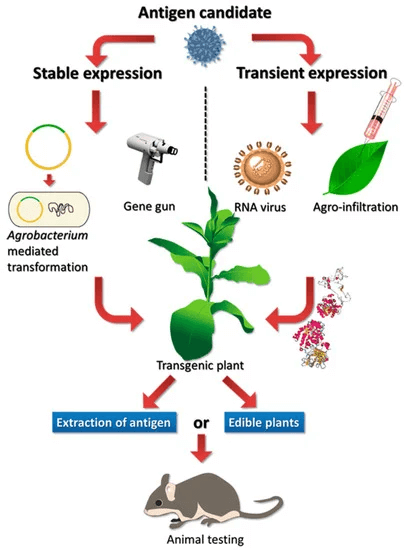

An example of the basic approach and its advantages is illustrated by the development of a candidate COVID-19 vaccine by Medicago, a Canadian company. Medicago developed a virus‐like particle (VLP) of the SARS‐CoV‑2 virus only 20 days after obtaining the virus’s genetic sequence. Instead of using egg‐ or animal cell‐culture‐based methods to produce a vaccine, this technology inserts a genetic sequence that encodes the spike protein of the COVID virus into Agrobacterium, a common soil bacterium that is taken up by plants. The resulting genetically modified plants produce a VLP that acts as a vaccine. The VLPs are similar in size and shape to actual coronavirus but lack viral or plant nucleic acid and are thus noninfectious.

Previously, Medicago had made VLPs that contain the influenza virus hemagglutinin protein and demonstrated their safety and efficacy in animal models as well as in human clinical trials. The cost of producing a plant‐made vaccine based on VLPs is small compared to its conventional counterpart. Medicago estimates that biological proteins such as vaccines and monoclonal antibodies could be obtained from genetically engineered tobacco plants at 0.1% of the cost of current methods. Moreover, these plant‐derived pharmaceuticals remain stable at room temperature for long time periods.

A similar approach is being taken by Kentucky BioProcessing (KBP) to create a COVID vaccine. Scientists at the company copied a portion of the SARS‐CoV‑2 virus and inserted it into the Nicotiana benthamiana plant (a close relative of tobacco) for rapid reproduction. These plants are then harvested and this inactive virus “fragment” is extracted and chemically attached to their proprietary microscopic nanoparticle. That particle is the vector, or carrier, to form the vaccine antigen complex that, when injected, stimulates an immune response. This KBP vaccine (and a similar one to prevent influenza) is currently in clinical trials. An advantage of KBP’s approach is that the plant used for production is not used for food, avoiding concerns about possible contamination of food products.

Regulating biopharming

Although biopharming has been under development in academic labs for over 20 years, the path to commercialization has been slow and inconsistent, in large part because of imposing regulatory hurdles. For example, more than a decade ago, a biotech company called Ventria Bioscience solicited the Food and Drug Administration to grant “generally recognized as safe” (GRAS) status to two human proteins, lysozyme and lactoferrin, synthesized in genetically engineered rice. These proteins were intended for use in oral rehydration solutions to treat diarrheal diseases. Research in Peru had shown an oral‐rehydration solution with the proteins extracted from Ventria’s rice substantially lessens the duration of diarrhea and reduces the rate of recurrence—a near‐miraculous advance for people in the developing world. However, Ventria never received any response from the FDA and the product was never marketed.

Without clear, predictable, and reasonable regulatory frameworks, it isn’t surprising that pharmaceutical companies, most of which have little experience in working with plants, are reluctant to make large upfront investments in this technology. Despite these hurdles, commercial biopharming has expanded, and large‐scale manufacturing facilities have been constructed in the United States, United Kingdom, and elsewhere. Companies such as Medicago, iBio and KBP can currently process thousands of kilograms of plant biomass grown in greenhouses into highly purified pharmaceutical proteins. None of these companies yet has an approved vaccine, but others, such as the UK’s Leaf Expression Systems, have begun to sell a small number of biopharmed diagnostic products and laboratory reagents, none of which are currently for human use.

It can be challenging to confine entire plant‐based protein expression systems within a clean room or greenhouse environment to conform with Current Good Manufacturing Practices (CGMPs). Nevertheless, the use of contained systems for plant cultures has helped to lessen various regulatory and safety concerns that might constrain production in plants cultivated in open fields.

No plants for biopharming have been approved for cultivation in commercial field production. Some work is taking place in approved, confined research field trials, which require isolation, toxicity data, and oversight by inspectors to witness disposal of residual plant material. Biopharming has, up to now, been restricted to laboratories and greenhouses to prevent introduction into the outdoors environment. These restrictions are a response to concerns such as the possible movement of pollen and the unintentional introduction of plant material containing bioactive substances into food supply chains and accidental consumption by people, livestock, or wildlife.

In 2003, the U.S. Department of Agriculture announced onerous new rules for testing crops engineered to produce pharmaceuticals. The ostensible objective of the regulation is to avoid contaminating food supplies with drugs, especially when edible crops are used to produce them. But concerns of the food industry and regulators that biopharmed plants could contaminate food products are overblown, and in any case such risk can be mitigated in several ways.

Even if biopharmed crops were to contaminate food crops, how likely is it that consumers would find harmful amounts of prescription drugs in their corn flakes, pasta, or tofu? A combination of factors—including natural selection, farmers pursuing their own commercial self‐interest, liability concerns, and the vast size of the U.S. food supply—all militate against such a possibility.

Gene flow is a ubiquitous biological fact of life. All crop plants have wild relatives somewhere, and some gene flow commonly occurs if the two populations are grown sufficiently close together. Thus, although genes could be transferred from a crop that has been modified to synthesize a pharmaceutical, the recipient plant is likely to proliferate only if the gene that has moved confers a selective advantage. Such occurrences should be uncommon with biopharming because, most often, the added drug‐producing gene should not confer on the recipient any selective advantage and would be more likely to put the plant at a selective disadvantage. Thus, if such a gene were to be transferred into a food crop, it might persist at a low level in the affected crop population for many generations, but we would expect its ability to proliferate and cause significant contamination of the food crop to be limited.

Gene transfer is an age‐old consideration for farmers. Farmers in North America and elsewhere, who grow many hundreds of crops—virtually all of which (save only wild berries and wild mushrooms) have been genetically improved in some way—have meticulously developed strategies for preventing pollen cross‐contamination in the field when and if it is necessary for commercial reasons. For example, plant breeders’ guidelines have traditionally called for keeping distinct varieties of corn—a wind‐pollinated crop—at least 660 feet apart. At this distance, the two corn varieties will not hybridize to any great extent, even if small amounts of pollen might still drift between the fields. Even without government oversight, biopharmers themselves strive to keep their specialty corn sufficiently far from ordinary cornfields, lest their highly valuable drug‐producing crops suffer contamination from the food crops.

Finally, as in the KBP COVID vaccine example above, biopharming can be performed in non‐food crops such as tobacco and its relatives.

Conclusions

Many biopharmed vaccines and other biologics have been shown to be cheap, safe, and efficacious, and do not require refrigeration or sophisticated medical equipment to distribute them. But these drugs have not yet entered the marketplace in part because of regulatory constraints.

When new restrictions on biopharmed crops were announced in 2003, then–agriculture secretary Ann Veneman told reporters, “It’s very important that we regulate in a way that allows this technology to proceed, so we can reap the benefits of it.” Instead, the department is regulating in a way that will ensure that the field is stigmatized, that biopharming’s research costs are hugely inflated, that only very high‐value‐added products will be candidates for development, and that consumers ultimately will see few biopharmed drugs in the pharmacy. Moreover, in these circumstances there is little chance that pharmaceutical companies will develop many products designed for less developed countries where heat‐stable, biopharmed drugs and vaccines could revolutionize health care.

Henry I. Miller, a physician and molecular biologist, was the founding director of the FDA’s Office of Biotechnology. He is the Glenn Swogger Distinguished Fellow at the American Council on Science and Health. Find Henry on Twitter @henryimiller

A version of this article was posted at Cato Institute and is used here with permission. Check out Cato Institute on Twitter @CatoInstitute